Repairing a dead TP-Link TL-PA211 Powerline Ethernet Adapter (Part 2)

Posted by Kev on

This post follows on from my earlier one where I opened up my broken TP-Link TL-PA211 Powerline Ethernet adaptor ready to replace the faulty capacitor.

The repair didn’t take very long and was quicker than dismantling the adaptor! To fix the unit you’ll need the following:

- A soldering iron - The exact one I have isn’t listed on eBay any more but any should be sufficient.

- Solder (not sure what type mine is)

- Some way of removing the old solder (De-soldering pump or braid. I used braid)

- Some flux to clean up the hole after removing the old solder

- A replacement capacitor.

Some comments from my last post suggest it’s possible to use a higher rated capacitor but I’m not sure what the benefit the higher rating brings. Please leave a comment if you can enlighten me 🙂

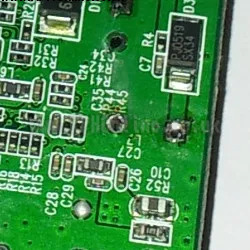

I used the braid to soak up the solder around the legs of the broken capacitor. Eventually you’ll be able to pull the capacitor off the board. I needed to use the braid a little more to clean the holes to allow the new capacitor in. This was how it looked after removing the faulty part:

I then cleaned up the hole with some flux. I applied the liquid flux I have with a small paintbrush; this helped me to make sure it only went on to the surfaces I intended to solder.

Now you can push the new capacitor in making sure it is the correct way round. The negative side should line up with the white part of the printed guide on the PCB.

On the underside of the PCB let the solder flow into the gap between the leg and the edge of the hole. It should fill the gap and, when cool, provide a nice strong connection. If you push on the capacitor there should be no movement below.

If you are happy with your soldering you need to cut the excess wire from the legs.

Whilst replacing the capacitor I noticed that I needed to carry out another quick repair. Because I hadn’t de-soldered the connections to the pins of the plug the PCB had remained attached during the repair. The regular flexing of these as I replaced the capacitor had caused one of the joints to split away from the metal strip. I managed to fix this joint by applying heat from the soldering iron to it and letting the solder join back onto the metal.

Pushing the PCB back into the case was quite tough as there is very little room to manoeuvre with the network port and reset button getting in the way! After some pushing and shoving I got it back together and plugged it into the power socket. No smoke or flames appeared which is always a good sign after doing work such as this. All three lights then came on and the unit started talking to my network as if nothing had ever gone wrong.

Hopefully, when I upgrade to the 500Mbps versions of these in the future, TP-Link may have a unit that will last a bit longer.

Disclaimer: If you do attempt to open up and fix your Powerline adaptor I cannot be held responsible for any damage that may occur to you, the adaptor or your surroundings. Be careful! Make sure you replace the parts with the same type and rating.

Comments from wordpress will appear here once I’ve copied them over 👍

Categories:

Repair